Products

December 18, 2025

Steel strapping have run for a long time in Indian warehouses despite its major problems. Injuries from sharp edges and recoil, rust stains on finished goods, […]

November 15, 2025

Introduction Most cargo damage doesn’t happen because strapping fails—it happens because someone made a preventable mistake during setup. Wrong buckle size, bad tensioning, twisted straps, worn […]

November 15, 2025

Introduction Your strapping fails at the worst possible time—mid-transport, after the truck hits rough road, when the load shifts just enough to snap a weak seal. […]

November 12, 2025

Introduction Your warehouse floor tells a story. It’s written in sliced palms, corroded straps, and workers who flinch when they reach for steel banding tools. The […]

November 12, 2025

Introduction Heavy load failures during transport cost logistics operations millions annually when buckles break, straps slip loose, or joints fail under stress. The problem isn’t strap […]

October 18, 2025

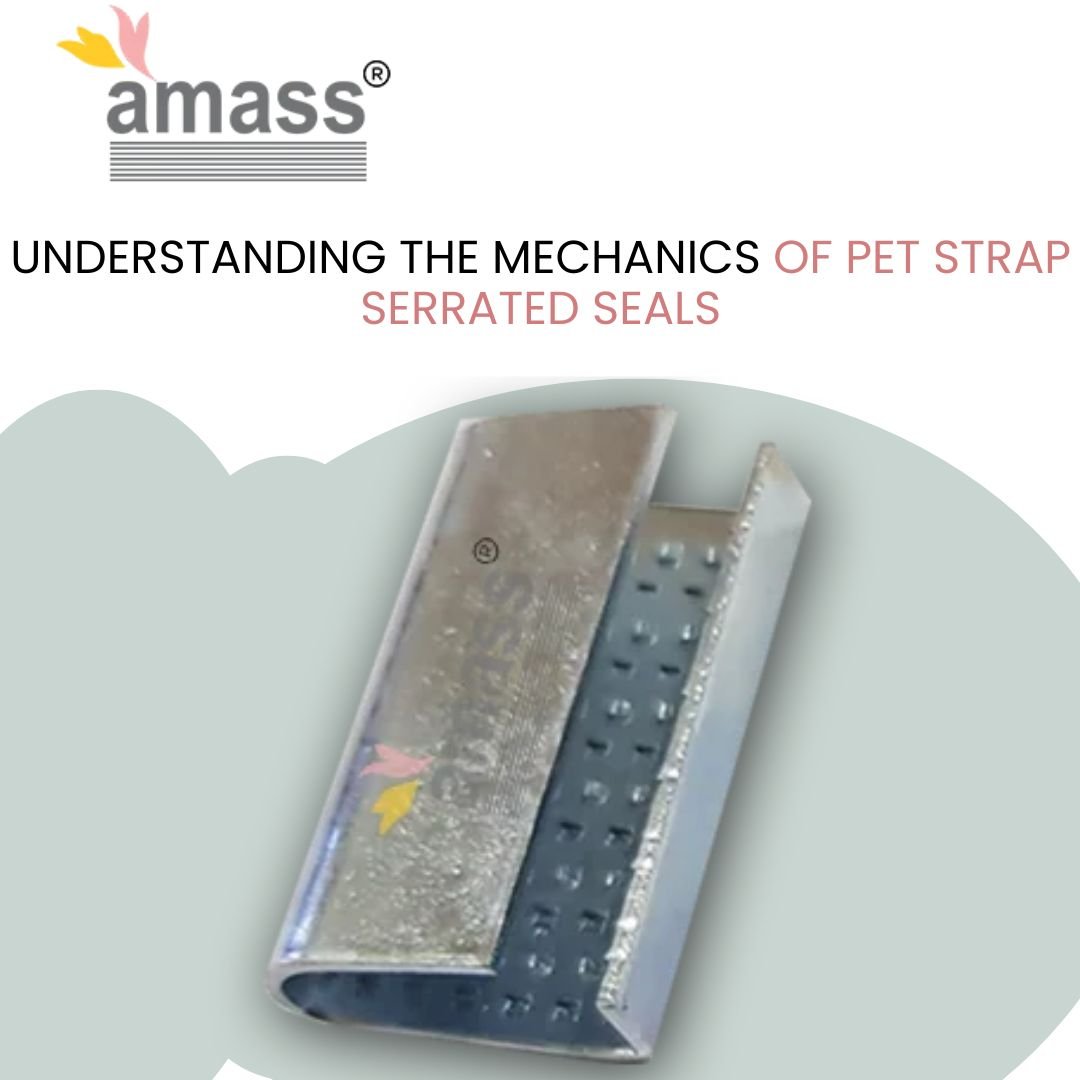

Introduction Packaging operations waste thousands annually from seal failures where straps slip loose, loads shift during transport, and cargo arrives damaged. Serrated seals solve this mechanical […]

October 15, 2025

Introduction Logistics operations lose up to 12% of packaged goods annually due to inadequate load securing methods that fail under stress, vibration, or weather exposure. Composite […]

October 9, 2025

Steel strapping has injured more warehouse workers than most operations managers admit. Between sharp edges that slice through gloves and the violent recoil when tension releases, […]

September 22, 2025

This is a hands-on, no-nonsense field manual for operators, supervisors, and maintenance leads who run strapping machines every day. The consistency you want—from clean welds to […]