Why Stainless Steel Buckles Are Ideal for Industrial Applications?

Understanding the Mechanics of PET Strap Serrated Seals

October 18, 2025

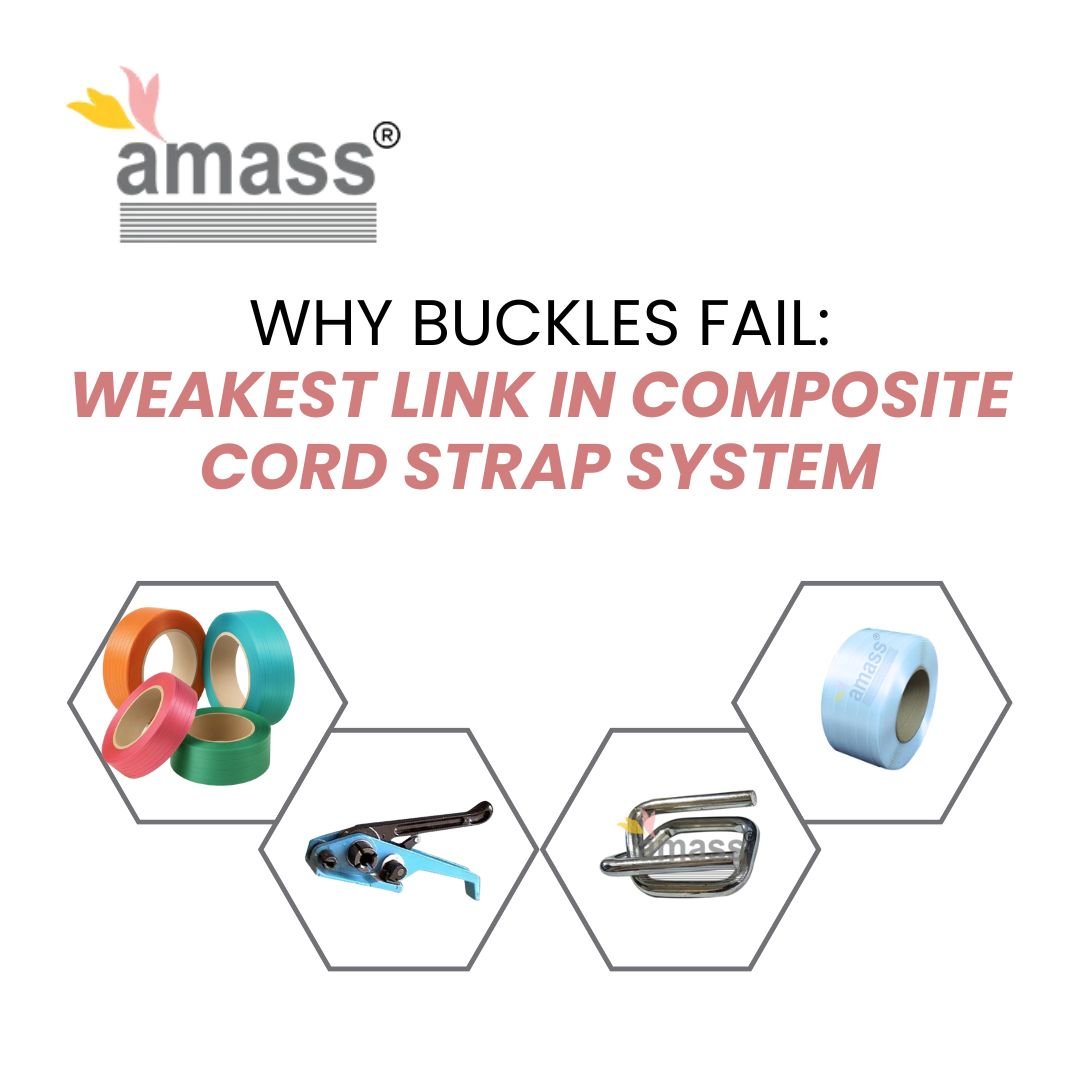

Best Composite Cord Strap & Buckle System for Heavy Loads

November 12, 2025Introduction

Industrial operations face cargo failures, equipment damage, and safety incidents each year from buckles that corrode, deform under pressure, or fail at critical load points. Stainless steel buckles eliminate these risks while handling loads from 1 to 10 tons without visible deformation. Made from corrosion-resistant alloys like 304 or 316 grade steel, these buckles maintain structural integrity in marine environments, chemical exposure, and extreme weather conditions. This article explains why stainless steel buckles outperform alternatives, where the material advantages matter most, and how to select the right grade for specific industrial demands.

Superior Strength Under Heavy Loads

Stainless steel buckles deliver tensile strength ratings between 500 MPa and 550 MPa depending on the grade. A 25mm ratchet buckle rated at 700 kg breaking strength can handle 350 daN lashing capacity without permanent deformation. Heavy-duty 50mm models support loads ranging from 5 to 10 tons in industrial machinery securing and warehouse tie-down systems.

Testing data shows that when tensile load reaches 7.0 kN, quality stainless steel buckles exhibit no deformation or damage. The material’s microstructure resists cracking, bending, and failure under significant stress. This strength-to-size ratio allows smaller buckles to replace bulkier alternatives without compromising safety margins.

Corrosion Resistance That Extends Service Life

Grade 304 for General Industrial Use

304 stainless steel contains 18% chromium and 8% nickel, providing medium corrosion resistance suitable for indoor warehousing, transport, and general strapping applications. This grade performs well under normal conditions but may degrade when exposed to saltwater or high-humidity environments over extended periods.

Expected lifespan for 304 buckles ranges from 5 to 8 years in typical industrial settings. The material costs less than premium grades while delivering reliable performance for operations that don’t involve marine exposure or harsh chemicals.

Grade 316 for Marine and Chemical Environments

316 stainless steel includes 2-3% molybdenum, which dramatically enhances resistance to chloride corrosion. This addition makes 316 buckles ideal for maritime shipping, offshore platforms, coastal construction, and chemical processing facilities. The material withstands saltwater, moisture, and aggressive chemicals without rusting or losing mechanical properties.

Service life for 316 buckles exceeds 10 years even in harsh marine conditions. While raw material costs run 20-30% higher than 304 due to molybdenum content, the extended durability and reduced replacement frequency offset the initial price difference.

Operational Safety and Handling Benefits

Stainless steel buckles feature smooth edges and stable locking mechanisms that reduce workplace injuries during installation and removal. The material doesn’t splinter or create sharp fragments when cut under tension, unlike ordinary steel that can recoil dangerously. Ratchet designs allow controlled tensioning without excessive manual effort, which prevents over-tightening that damages straps or cargo.

The buckles maintain grip on straps even during sudden jolts, vibrations, or load shifts common in road transport and maritime shipping. 316 grade steel also qualifies as medical-grade material, making it hypoallergenic and suitable for food-grade applications where skin contact or contamination concerns exist.

Versatility Across Industrial Sectors

Cargo Securing and Logistics

Stainless steel buckles secure pallets, crates, and heavy machinery on trucks, trailers, and freight containers for road and rail transportation. Load capacities range from 1 to 5 tons for standard cargo strapping, with quarterly maintenance intervals recommended for high-use scenarios.

Construction and Heavy Equipment

Industrial tie-down systems use stainless steel buckles for securing scaffolding, bundling construction materials like rebar and pipes, and anchoring heavy equipment during on-site storage. The buckles handle irregular load shapes and provide adjustable tension for materials that expand or contract.

Marine and Offshore Operations

316 grade buckles secure boats, marine equipment, docks, and offshore structures where constant saltwater exposure would corrode lesser materials. Bi-annual maintenance suffices for marine applications due to the material’s superior corrosion resistance.

Textile and Manufacturing

Stainless steel buckles fasten straps around bundles of fabrics, yarns, and carpets during storage and transport. They provide adjustable tensioning for products like sails, tents, and awnings where precise load distribution matters.

Long-Term Cost Efficiency

The buckle market reached USD 3.45 billion in 2023 and continues growing at 4.8% annually as industries prioritize durable fastening solutions. Stainless steel buckles require minimal maintenance—cleaning to remove salt and debris after marine use, quarterly inspections for industrial applications, and light lubrication of moving parts.

Material durability reduces replacement frequency compared to carbon steel buckles that rust or plastic alternatives that crack under UV exposure. The buckles can be reused across multiple shipments when properly inspected for wear, further lowering per-use costs. Recyclability at end of life adds environmental value without disposal complications.

FAQs

What load capacity do I need for my application?

Match buckle width and rating to maximum expected load. Standard 25mm buckles handle up to 700 kg breaking strength, while 50mm heavy-duty models support 5-10 tons. Always consider working load limit (WLL) at 50% of breaking strength for safe operation.

When should I choose 316 over 304 stainless steel?

Use 316 grade for marine environments, coastal areas, chemical exposure, or any application involving saltwater and high humidity. Select 304 for general indoor warehousing, transport, and strapping where corrosive elements aren’t present. The 20-30% price premium for 316 pays off through extended service life in harsh conditions.

How often should stainless steel buckles be inspected?

Industrial applications require quarterly inspections, marine uses need bi-annual checks, and outdoor construction benefits from annual reviews. Look for cracks, corrosion, deformation, or wear on locking mechanisms during each inspection.

Can stainless steel buckles be reused?

Yes, when properly maintained and inspected for damage. Clean buckles after use, especially following marine or chemical exposure, and store in dry conditions to maximize reuse cycles.

Conclusion

Stainless steel buckles deliver measurable advantages in strength, corrosion resistance, safety, and long-term cost efficiency for industrial operations. The choice between 304 and 316 grades depends on environmental exposure, with 316 providing superior performance in marine and chemical settings. Load capacities from 1 to 10 tons cover applications from general cargo strapping to heavy industrial machinery securing.

Contact us for technical specifications and bulk pricing on stainless steel buckles matched to your operational requirements.

Amass Strap manufactures high-grade stainless steel buckles in both 304 and 316 alloys for industrial strapping applications. Our buckles meet international safety standards with load ratings from 700 kg to 10 tons, available in 13mm through 50mm widths. We provide custom sizing, material grade selection guidance, and competitive pricing for bulk orders across manufacturing, logistics, construction, and marine sectors.

Visit amass-strap.com to request technical datasheets, compare grade specifications against your environmental conditions, or schedule a consultation with our engineering team for application-specific recommendations.